Pharmapack emphasizes reliability and longevity in its packaging systems, particularly for experienced pharmaceutical manufacturers. They design solutions like the LFBI series to ensure smooth operation, minimizing maintenance issues while optimizing production efficiency. One key feature of their horizontal cartoning machines is the automatic lubrication supply system, which precisely regulates lubricant amounts to maintain optimal performance.

Integration with Horizontal Cartoning Machine Technology

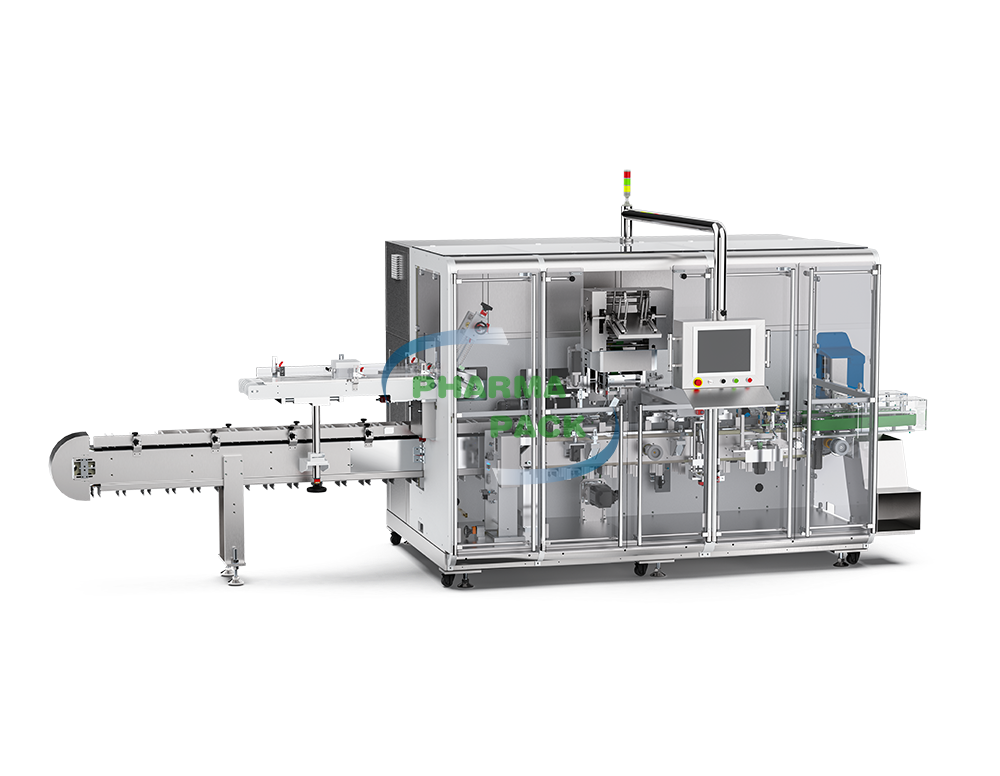

They collaborate with advanced horizontal cartoning machine developers to provide reliable systems capable of handling complex pharmaceutical packaging. The LFBI-10, for example, ensures that products are positioned and transferred accurately through the infeed conveyor and marking stations. By combining robust horizontal cartoning machine design with intelligent lubrication control, Pharmapack prevents wear and maintains consistent machine performance, which is essential for experienced manufacturers operating high-speed lines.

Automatic Lubrication System and Operating Hours Monitoring

The LFBI-10 includes an automatic lubrication supply system that measures operating hours to determine the precise amount of lubricant required for each bearing. This system prevents over- or under-lubrication, which could lead to mechanical wear or interruptions in production. By synchronizing lubrication with machine usage, Pharmapack ensures that the cartoner packaging machine operates smoothly throughout each production cycle. Sensors and integrated controls monitor the movement of product buckets, flap folders, and other components to calculate lubrication needs, maintaining machine efficiency and extending equipment lifespan.

Supporting Consistent Production and Maintenance

The LFBI-10’s design integrates both the lubrication system and the cartoning process. After cartons are squared, marked, and filled with leaflets, they move along toothed belt transporters for flap folding and final ejection. The automatic lubrication system works in parallel with these operations, keeping bearings properly maintained without interfering with production speed. This seamless integration allows experienced operators to focus on high-volume output, knowing that the cartoner packaging machine is continuously protected and performing at peak efficiency.

Conclusion

Pharmapack demonstrates that precise lubrication based on operating hours is essential for the reliable performance of horizontal cartoning machines. By combining intelligent automatic lubrication systems with well-engineered cartoner packaging machines, they provide experienced pharmaceutical manufacturers with machines that run efficiently, reduce wear, and ensure consistent high-speed packaging. This approach enhances both production quality and machine longevity, supporting optimal operations across the entire packaging line.