Liquid Silicone Rubber overmolding has transformed how manufacturers create high-performance parts across various industries. By combining silicone with other materials like metals or plastics, LSR overmolding offers unique advantages such as reduced assembly time, enhanced durability, and superior precision. This article explores the process of LSR overmolding, its benefits, and how Henry Precision excels in providing efficient and high-quality solutions for manufacturers.

What is Liquid Silicone Rubber Overmolding

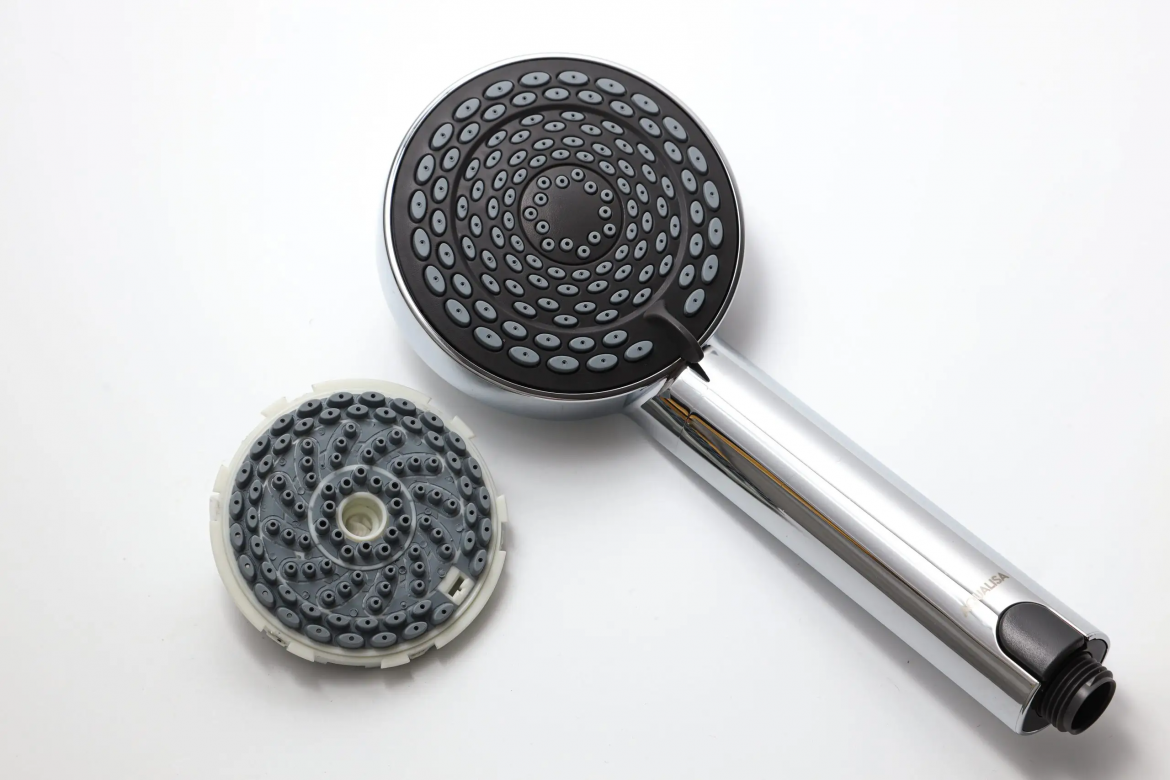

LSR overmolding is a process where a base material, often metal or plastic, is first molded, followed by the addition of a silicone rubber layer. This process results in a single, integrated component that combines the properties of both materials. In LSR overmolding, the silicone layer provides flexibility, water resistance, and shock absorption, which makes it an ideal choice for sensitive applications in industries like medical devices and automotive parts. Unlike traditional overmolding, LSR overmolding offers precision molding in clean room environments, ensuring high-quality output for demanding applications.

Advantages of Using LSR Overmolding in Manufacturing

One of the most significant advantages of LSR overmolding is the reduction in assembly steps, which directly translates to cost savings and faster production cycles. By eliminating the need for manual assembly, manufacturers can speed up their processes and deliver products to market more efficiently. Additionally, LSR overmolding is highly durable and resistant to wear and tear, making it ideal for parts that must endure harsh conditions, such as automotive seals and medical components. The versatility of LSR overmolding also allows manufacturers to combine different materials and create parts with improved performance, such as water-tight seals, better thermal stability, and enhanced resistance to shocks and vibrations.

Henry Precision’s Role in LSR Overmolding

Henry Precision has built a reputation for its expertise in overmolding silicone, offering customized solutions that meet the specific needs of industries such as automotive, medical, and consumer electronics. By utilizing state-of-the-art clean room environments and precise molding techniques, Henry Precision ensures the highest standards of quality and consistency. Their experience in handling complex parts and materials makes them a go-to partner for manufacturers looking to innovate and enhance their product lines. Whether it’s developing new designs or scaling up production, Henry Precision’s overmolding silicone solutions provide the reliability and efficiency needed to succeed in competitive markets.

Conclusion

Incorporating LSR overmolding into your manufacturing process can significantly improve product quality, reduce costs, and streamline production timelines. With Henry Precision’s expertise in this field, companies can rely on precise, high-performance solutions that meet the demands of modern industries. By combining innovation with efficiency, LSR overmolding presents an opportunity for manufacturers to enhance their product offerings and stay ahead in a rapidly evolving marketplace.